Industrial belts

Industrial Belt or V Belt (V-Belt) Construction, Types, by Size, Classification. … V-Belts are friction based power or torque transmitters. The power is transmitted from one pulley to the other by means of the friction between the belt and pulley. The rubber used as the base material plays a very vital role in this.The V-Belts are basically classified into 5 types or sections i.e. ‘A’, ‘B’, ‘C’, ‘D’ and ‘E’. The categorization of this is based on the cross sectional size of the belt and the amount of power to be transmitted by the belt.Conveyor Belt is the carrying medium of a belt conveyor system (often shortened to belt conveyor). A belt conveyor system is one of many types of conveyor systems. A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with a closed loop of carrying medium—the conveyor belt—that rotates about them

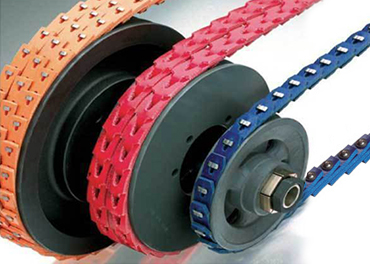

Industrial belts

- Vee belts

- Wrapped and cogged

- Timing belts

- Rubber and PU

- Variable speed belt

- Conveyor belt

- Perforated belt

- Link belt

- Sandwich belts

- Nylon and rubber